Sheet Metal Stamping Services

Furni Tech Life: Sheet Metal Stamping Services

Welcome to Furni Tech Life, your trusted partner for high-quality sheet metal stamping services. We specialize in transforming flat sheet metal into a variety of shapes using our state-of-the-art stamping techniques.

- Our team of skilled professionals is adept at handling a wide range of materials including stainless steel, aluminium, brass, copper, and more. We are committed to delivering precision-engineered components that meet your exact specifications.

Furni Tech Life: Sheet Metal Stamping Services

Welcome to Furni Tech Life, your trusted partner for high-quality sheet metal stamping services. We specialize in transforming flat sheet metal into a variety of shapes using our state-of-the-art stamping techniques. Our team of skilled professionals is adept at handling a wide range of materials including stainless steel, aluminium, brass, copper, and more. We are committed to delivering precision-engineered components that meet your exact specifications. Our expertise extends to various industries such as automotive, aerospace, electronics, and construction.

At Furni Tech Life, we understand that precision is key in sheet metal stamping. Our team uses advanced technology and equipment to ensure that each component is manufactured to the highest standards. We take pride in our ability to produce parts with tight tolerances and complex geometries. We work with a wide range of materials to suit different applications and requirements. Whether you need components made of stainless steel for its corrosion resistance, aluminium for its lightweight properties, or brass for its electrical conductivity, we have you covered.

Quality is at the heart of everything we do. We have a rigorous quality control process in place to ensure that every part we produce meets our high standards and your expectations. Our commitment to quality has earned us the trust of our clients. Choosing Ferni Tech Life means choosing a partner committed to your success. We offer competitive pricing, quick turnaround times, and exceptional customer service. Our team is dedicated to helping you bring your vision to life.

We understand that cost is a crucial factor in any project. That’s why we strive to offer the most competitive pricing in the industry without compromising on quality. We know that time is of the essence in your business. That’s why we’re committed to delivering your components on time, every time. At Ferni Tech Life, we believe in building long-term relationships with our clients. Our team is always available to answer your questions, discuss your needs, and provide expert advice.

Quality Assurance:

At Furni Tech Life, we adhere to stringent quality control measures at every stage of the stamping process to ensure the highest standards of quality and precision.

Advanced Technology:

We leverage the latest technology and machinery to provide efficient and cost-effective solutions for all your sheet metal stamping needs.

Custom Solutions:

We understand that every project is unique. Our team works closely with you to understand your requirements and deliver custom solutions that align with your business goals.

Timely Delivery:

We value your time. Our streamlined processes and dedicated team ensure that your project is completed on time, every time.

Our Process

Our sheet metal stamping process involves several steps:

Quality is at the heart of everything we do. We have a rigorous quality control process in place to ensure that every part we produce meets our high standards and your expectations. Our commitment to quality has earned us the trust of our clients. Choosing Ferni Tech Life means choosing a partner committed to your success. We offer competitive pricing, quick turnaround times, and exceptional customer service. Our team is dedicated to helping you bring your vision to life.

Design

Our team collaborates with you to understand your requirements and create a design that meets your specifications.

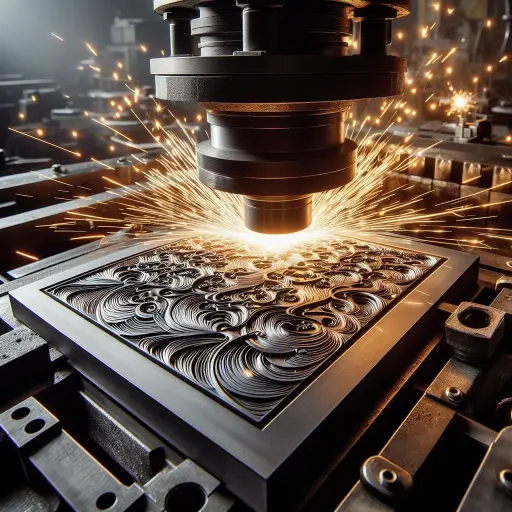

Stamping

The flat sheet metal is then fed into a stamping press which uses custom-made dies to transform it into the desired shape

Material Selection

Click edit button to change this text. Lorem ipsum dolor sit amet consecte.

Finishing

The stamped parts are then subjected to various finishing processes such as cleaning, deburring, painting, or coating as per your requirements.

Our All Services

Furni Tech Life is a leading innovator in the realm of Plastic Molding Components, Sheet Metal Parts & Moulds manufacturing.

Sheet Metal Stamping

It revolutionizes manufacturing by efficiently shaping metal components with precision, catering to diverse industrial needs

Fabrication

Fabrication integrates cutting-edge techniques to craft bespoke products across industries, ensuring precision and durability.

Welding

Welding, a fundamental fabrication process, fuses materials together through heat and pressure, crucial for constructing structures

Critical Assembly

Meticulous joining of components ensuring product functionality, safety, and reliability with stringent quality control.

Injection Moulding Parts

Precise production method using molten material injected into molds for efficient component creation.

Blow Moulding

Shaping molten material into hollow objects by inflating a heated plastic tube within a mold cavity

Extrusion Moulding

shaping molten material by forcing it through a die to create continuous profiles, tubes, or sheets

Mould Manufacturing

Crafting precise molds for shaping materials in various manufacturing processes, pivotal for ensuring consistency and quality

Powder Coating

Applying dry powder electrostatically and curing it with heat to form a durable and decorative finish on surfaces

We Provide the Best Service in Industry

For inquiries or assistance, please don’t hesitate to contact